Workers at Ford factories in the USA will wear wristbands made by South Korean tech giant Samsung – and similar to the one above – that buzz to help maintain social distancing, Bloomberg news agency reports.

The ‘fitness-like’ devices are supposed to vibrate when employees come within about 1.8m of each other. The experiment will initially be trialled by 12 employees, a Ford spokesperson told Bloomberg.

If the technology proves effective, the devices could be used more widely once Ford restarts production on its US assembly lines after a six-week shutdown.

“The aim is to keep workers from breaching the distance that health experts recommend to avoid spreading the coronavirus,” Bloomberg said.

“The aim is to keep workers from breaching the distance that health experts recommend to avoid spreading the coronavirus,” Bloomberg said.

Ford is also likely to subject factory workers to a thermal-imaging scan to detect a fever, a practice rolled out at other production facilities around the world, not only in the car industry. The report said Ford will also provide staff with masks and, in some cases, plastic face shields.

The Samsung wristbands are use ‘near-field’ software made by Radiant RFID, a company based in Austin, Texas. The devices use “Bluetooth short-wave and low-power technology to detect proximity and clustering of workers”, the report said.

Workers will receive a vibration and a colour-coded warning on the watch to let them know when they are closer than 1.8m to another person.

“Supervisors also receive alerts and reports that can be used to monitor social distancing and clustering in the workplace,” Bloomberg reported.

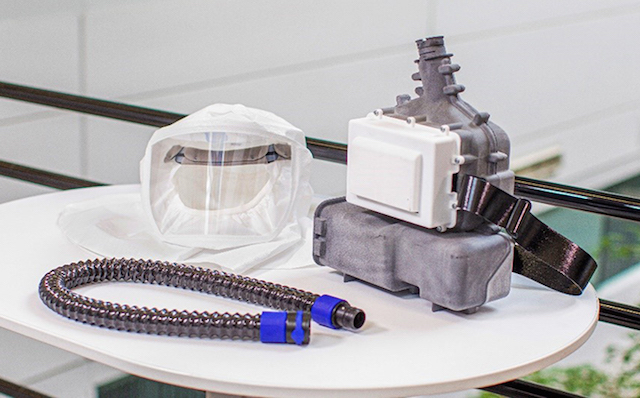

Meantime, as General Motors is about to ramp up full scale production of medical ventilators at one of its decommissioned plants, Ford is expanding its efforts to produce more than 3 million face shields, tens of thousands of reusable hospital gowns (using airbag material), and thousands of powered air-purifying respirators (PAPRs), pictured above.

“We knew that to play our part helping combat coronavirus, we had to go like hell and join forces with experts like 3M to expand production of urgently needed medical equipment and supplies,” said a statement from Jim Baumbick, vice president of Ford’s product line management.

“In just three weeks under Project Apollo, we’ve unleashed our world-class manufacturing, purchasing and design talent to get scrappy and start making personal protection equipment and help increase the availability and production of ventilators.”