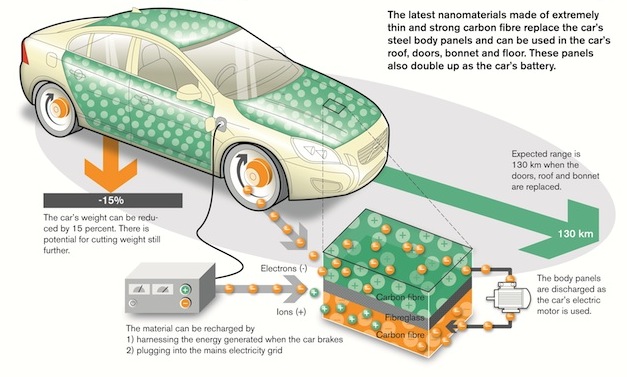

Volvo has developed cutting-edge technology to replace the large and bulky battery packs used in today’s electric cars.

It’s a composite nanomaterial that can transform a car’s bodywork into batteries that can store electricty,

The material is made from strong, thin layers of carbon fibres blended with a polymer resin, with nano-structured batteries and supercapacitors sandwiched in between.

It can be used to replace a car’s conventional metal bodywork, including the doors, roof and bonnet, with Volvo claiming the expected electric range the panels could power would be 130km/h.

This new material can be recharged by regenerative braking, and by plugging the car in to the mains.

Volvo claims that the new material recharges and stores energy faster than current lithium-ion batteries, but doesn’t suffer from degradation as quickly as standard batteries because there is no chemical process involved in charging and discharging them.

To prove the concept, Volvo has built an S80 prototype with two parts made from the new material.

The car features a new bootlid that can store enough power to replace a car’s standard battery, and weighs less than the standard item.

Under the bonnet, the scuttle and strut brace are formed from the new material, too, adding stiffness to the car’s front end, while also being able to store enough power to replace the smaller battery that powers the S80’s stop-start system.

Volvo says this saves more than 50 per cent in weight and is powerful enough to supply energy to the car’s 12 Volt system

Volvo also claims that the material would cut overall weight by 15 per cent, if the doors, roof and bonnet were made from the new material.

Such a cut would mean a roughly 250kg loss of weight in the flagship S80 model.

The project to develop the material was driven by the European Union and began in 2010.